Why choose Atlas Copco or Sandvik for mining and importance of parts

A single equipment breakdown in a mining operation can lead to thousands of dollars in lost revenue, delays in production, and potential safety hazards. To mitigate these risks, mining companies must invest in reliable equipment and top-quality spare parts. Two industry giants, Sandvik and Atlas Copco, have established themselves as leaders in providing cutting-edge mining solutions. In this blog post, we'll explore why these brands are preferred choices for mining operations and the crucial role of quality spare parts in maximizing equipment lifespan and performance.

Why Choose Sandvik for Mining?

1. Innovation and Technology: Sandvik is renowned for its continuous innovation and technological advancements in mining equipment. Their machinery is designed to improve efficiency and productivity, ensuring that mining operations are both cost-effective and sustainable.

2. Reliability and Durability: Sandvik equipment is built to withstand the harshest mining environments. Their machines are known for their durability, minimizing downtime and maximizing productivity. possesses.

3. Comprehensive Range: From drilling rigs and crushers to loaders and underground vehicles, Sandvik offers a comprehensive range of mining equipment to meet the diverse needs of the industry.

4. Safety: Safety is paramount in mining, and Sandvik prioritizes this in their equipment design. Their machines are equipped with advanced safety features to protect workers and ensure safe operation.

Why Choose Atlas Copco for Mining?

1. Efficiency and Performance: Atlas Copco is synonymous with high-performance mining equipment. Their machines are engineered for maximum efficiency, ensuring that mining operations are both productive and profitable.

2. Sustainability: Atlas Copco places a strong emphasis on sustainability. Their equipment is designed to minimize environmental impact, reducing energy consumption and emissions.

3. Versatility: With a wide range of equipment, including drills, loaders, and rock tools, Atlas Copco caters to various mining applications, ensuring you have the right tools for the job.

4. Global Support Network: Atlas Copco offers a robust global support network, providing customers with access to spare parts, technical support, and maintenance services wherever they are.

The Importance of Quality Spare Parts

Using quality spare parts is crucial for the longevity and optimal performance of mining equipment. Here's why:

1. Increased Lifespan: High-quality spare parts ensure that your equipment runs smoothly and lasts longer. Inferior parts can cause frequent breakdowns, reducing the overall lifespan of the machinery.

2. Improved Performance: Spare parts are designed to fit perfectly and work seamlessly with your equipment, ensuring optimal performance and efficiency.

3. Reduced Downtime: Quality spare parts are less likely to fail, which means less downtime for your mining operations. This leads to increased productivity and profitability.

4. Cost Savings: While quality spare parts might have a higher upfront cost, they save money in the long run by reducing the frequency of repairs and replacements, as well as minimizing downtime.

Why Choose Worldclass Machinery Solutions Parts?

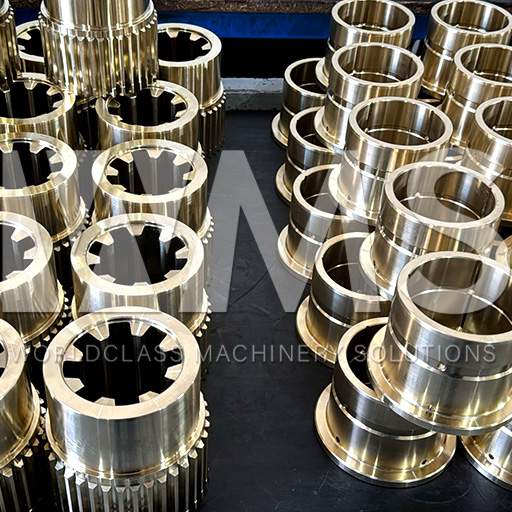

At WMS Drill Parts, we understand the critical role that quality spare parts play in mining operations. Here's why you should choose us for your spare parts needs:

1. Wide Range of Products: We offer a comprehensive range of spare parts for Sandvik and Atlas Copco equipment, ensuring you have access to the parts you need when you need them.

2. Quality Assurance: We engineer and manufacture premium aftermarket parts and all our spare parts are of the highest quality, ensuring durability and reliability, keeping your vehicle running smoothly.

3. Competitive Pricing: We offer competitive pricing on all our spare parts, providing value without compromising on quality.

4. Expert Support: Our team of experts is always available to provide technical support and advice, ensuring you get the right parts for your equipment.

5. Fast Delivery: We understand the importance of minimizing downtime, which is why we offer fast and reliable delivery services to get your parts to you as quickly as possible.

Conclusion

Choosing Sandvik and Atlas Copco for your mining operations is a decision that promises innovation, reliability, and efficiency. However, to ensure your equipment continues to perform at its best, using quality spare parts is essential. WMS Drill Parts is your trusted partner in providing top-quality spare parts that enhance the longevity and performance of your mining equipment. Contact us to learn more about our products and services or request a free quote today!