Spare Parts for Drill Rigs, Rock Drills & Mining Machinery

Welcome to Worldclass Machinery Solutions, Turkey's leading manufacturer and supplier of high-quality alternative spare parts for Atlas Copco, Epiroc, Sandvik, and Tamrock mining equipment. Our extensive inventory includes both new and carefully refurbished products for your mining equipment.

Comprehensive Solutions for Mining Operations

- New OEM-Quality Parts: Premium aftermarket components manufactured to exact specifications

- Renewed Components: Professionally refurbished parts offering exceptional value

- Second-Hand Equipment: Carefully inspected used machinery and components

- Custom Manufacturing: Tailored solutions for specialized applications

By paying attention to details, we ensure durability and precision by manufacturing each component in our facilities. From here, our products pass seamlessly through our modern distribution network and reach our valued customers with efficiency and reliability.

Our commitment to quality control ensures that every product meets the highest standards, enabling rig operators worldwide to provide reliable solutions for their critical equipment needs. We do not just deliver parts, we also reinforce our leading position in the industry by promising trust and reliability.

Spare Parts for Drilling Rigs

Each component plays a vital role in ensuring seamless functionality, from the smallest bolts to the most

intricate mechanisms. Whether it's a crucial replacement during routine maintenance or a swift response to

unexpected breakdowns, our comprehensive range of parts, component and tools ensures that downtime is

minimized and productivity maximized.

With focus on quality, durability and compatibility our parts for

drill rigs are engineered to exceed expectations, empowering drilling professionals to tackle the toughest

tasks with confidence and reliability.

Check Out Our Stock

Bestseller Products

Atlas Copco 3222 3232 51 Connection

Atlas Copco 3222 3232 51 Connection  Atlas Copco 3115 5207 00 Front part

Atlas Copco 3115 5207 00 Front part  Sandvik 874 560 09 U-seal

Sandvik 874 560 09 U-seal  Sandvik 550 378 33 Filter element

Sandvik 550 378 33 Filter element  Atlas Copco 0211 1410 03 Screw

Atlas Copco 0211 1410 03 Screw  Sandvik 856 811 29 O-ring

Sandvik 856 811 29 O-ring  Atlas Copco 3128209955 Check valve

Atlas Copco 3128209955 Check valve  Sandvik 551 679 87 Motor assembly hydraulic

Sandvik 551 679 87 Motor assembly hydraulic  Sandvik 551 796 00 Slide frame

Sandvik 551 796 00 Slide frame  Atlas Copco 4350 2650 45 Sealing bush

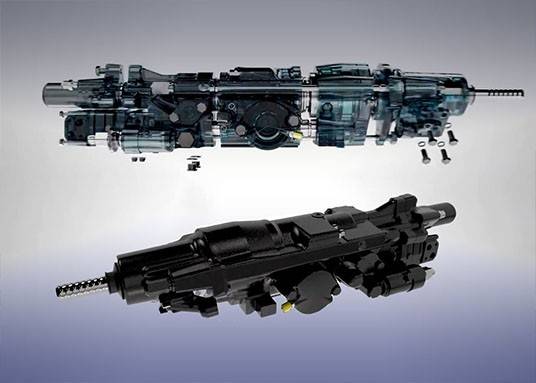

Atlas Copco 4350 2650 45 Sealing bush Rock Drill and Drifter Parts

Our comprehensive range of drifter replacement parts ensures seamless compatibility and optimal functionality,

whether it's a piston, seal, driver or valve.

With a commitment to production quality craftsmanship and

rigorous testing, our parts guarantee reliability and longevity, minimizing downtime and maximizing

productivity.

Check Out Our Online Catalog

Most Popular Products

Sandvik 550 229 34 Exhaust silencer

Sandvik 550 229 34 Exhaust silencer  Sandvik 552 177 42 Flushing device assembly

Sandvik 552 177 42 Flushing device assembly  Sandvik 236 078 48 Jaw rh

Sandvik 236 078 48 Jaw rh  Sandvik 550 136 96 Cable assembly

Sandvik 550 136 96 Cable assembly  Sandvik 550 261 58 Seal rod

Sandvik 550 261 58 Seal rod  Sandvik 777 225 41 Cartridge

Sandvik 777 225 41 Cartridge  Sandvik 151 539 78 Tie rod

Sandvik 151 539 78 Tie rod  Sandvik 550 227 81 Electrical assembly

Sandvik 550 227 81 Electrical assembly  Sandvik 141 693 68 Shim

Sandvik 141 693 68 Shim  Sandvik 73808303 Tee fitting

Sandvik 73808303 Tee fitting Let us Produce!

Can't you find a replacement for the part you have? Send us and let us produce for you! Here are the four steps of the part production process as a manufacturer of replacement parts for drill rigs and drifters. These steps represent the general process applied when a customer requests the production of the original part. Each step should be carefully managed, and quality should be maintained at the highest level to ensure customer satisfaction.

How it works?

Examination and Design of the Part : The process begins with the customer sending us the original part or providing detailed technical drawings. In this step, the part is thoroughly examined, and measurements are taken. Engineering and design work are then carried out to understand how the part functions, what materials it is made of, and what specific features it possesses.

Material Selection and Procurement : After the design is determined, appropriate materials need to be selected. This involves identifying the most suitable materials that will ensure the functionality and durability of the original part. Material procurement should be done from reliable and quality suppliers.

Production and Processing : The production process involves the processing, shaping, and assembly of the selected materials. CNC machines, lathes, milling machines, and other manufacturing equipment are used to produce the parts. Precise measurements and quality control steps are integral parts of this process.

Quality Control and Testing : The produced parts undergo rigorous quality control tests according to strict standards. These tests evaluate various factors such as dimensional accuracy, durability, strength, and functionality. Any defective parts are identified, necessary corrections are made, and after it is confirmed that they meet quality standards, they are delivered to the customer.

27+

Years

Manufacturing Experience

54757

Parts

In Our Catalogue

892+

Satisfied

Local and Worldwide Customers

Why WMS?

Uncompromising Quality - Built to Last

We are committed to delivering only the best. Each part or component we manufacture undergoes rigorous quality control processes to ensure it meets the highest industry standards. Our priority is quality, ensuring the reliability and longevity of your machinery.

Guaranteed Performance - Backed by Warranty

We are confident in the quality of our parts. If there is any manufacturing defect in the purchased part, we will promptly replace the part free of charge or provide a full refund, whichever you prefer. Your satisfaction is our top priority, and we stand behind the performance of our products.

Competitive Prices

We offer our premium spare parts and services at fair and competitive prices. Our goal is to provide value to our customers without compromising on the quality of the products you need to keep your equipment running smoothly.

World-wide Shipping

We deliver our high quality mining equipment parts to customers all around the world. No matter where your operations are located, we offer fast and reliable shipping to get the parts that you need, minimizing downtime.